![]() Email:sales04@bdhuazheng.com

Email:sales04@bdhuazheng.com

![]() Cellphone/ wechat/Whatsapp /Skype: +86 18330222302

Cellphone/ wechat/Whatsapp /Skype: +86 18330222302

1. Directly cause internal short circuits, leading to transformer burnoutAfter winding deformation, the distance between turns and coils changes, leading to localized insulation being compressed, rubbed, and damaged.The original support structure of the winding became loose, causing the conductors t

Strictly control the operating temperature and ensure proper heat dissipationExcessive temperature is the core cause of accelerated insulation aging and shortened lifespan of transformers. During operation, it is necessary to keep the radiator and cooling pipelines free of oil stains and blockages.

1、 Transformer factory/new manufacturing stage: precise quantitative detection of iron core lossThis stage of testing is a laboratory level precision test, which measures the core core loss through no-load testing and includes pre testing of iron loss for silicon steel sheet raw materials. The data

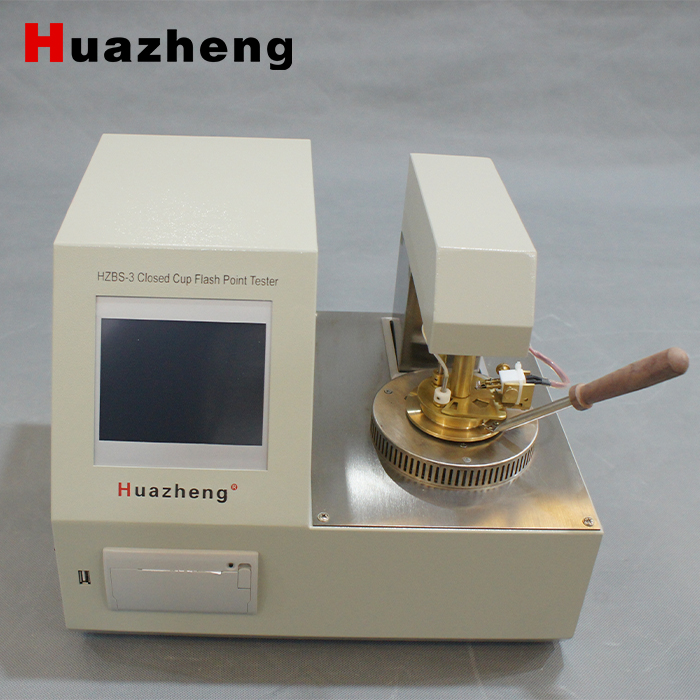

Assess the safety risks of insulating oilFlash point is the lowest temperature at which insulating oil can ignite when exposed to an external fire source under standard test conditions when oil vapor mixes with air to form a combustible mixture. It is a core safety indicator for measuring the flamma

Monitoring of power system transmission and distribution linksIn the operation and maintenance of power plants, substations, and transmission lines, three-phase power quality testers are used to monitor core parameters such as three-phase voltage, current imbalance, harmonic content, power factor, a